How to Build Padbol Courts?

Building a Padbol court is an exciting investment opportunity in one of the world’s fastest-growing hybrid sports. Padbol combines elements of football, tennis, and volleyball, played inside a 20 × 10 meter enclosed glass-and-net structure. The court itself greatly influences gameplay quality, safety, and overall durability. Therefore, the design and construction process must follow international Padbol Federation standards.

If you are considering building a padbol court for your club, hotel, sports complex, or as a new business venture, this guide explains the entire process step-by-step — from concept to playable court.

1. Site Analysis & Project Planning

Every successful Padbol court project begins with a detailed site analysis. Before any construction or manufacturing starts, two critical questions must be answered:

- Indoor or outdoor installation?

- How much space is available for construction and access?

Key assessments include:

- Soil condition and ground stability

- Drainage and water flow possibilities (for outdoor courts)

- Access for construction machinery and material transport

- Electrical and lighting requirements

Once the location is confirmed, a project layout plan is prepared showing court placement, entry points, spectator areas, and electrical infrastructure. Proper planning saves both time and money during installation.

2. Designing the Padbol Court

The design stage determines player safety, visual quality, and long-term durability. In this phase, a professional 3D layout and technical drawings are developed based on:

- Official court size: 20 x 10 meters

- Height of tempered glass walls (typ. 2.5–3 meters)

- Placement of rebound nets

- Lighting coverage

- Door and entry positioning

Structural calculations are performed to consider wind load, impact force, and environmental conditions. A proper design ensures the court meets federation standards and provides a premium player experience.

3. Manufacturing the Structure

After the design is confirmed, production begins.

The three primary elements of a Padbol court are:

- Steel structure (frame & columns)

- Tempered glass panels

- Elastic rebound nets

- Steel Structure

The main frame is manufactured from high-strength galvanized steel, ensuring:

- Anti-corrosion resistance

- Longevity in outdoor environments

- Structural rigidity

The steel is CNC-cut, welded, and painted or powder-coated according to project colors.

Tempered Glass: Padbol requires tempered safety glass, typically 10–12 mm thick, capable of absorbing strong ball impact and player collision. Each panel goes through edge polishing and stress tests before installation.

Rebound Net System: Special elastic nets are placed in designated areas to control ball rebound angles. These nets are tension-adjustable and tested for durability and elasticity.

A professional manufacturer tests every component — steel, glass, and net — before shipping to the installation site.

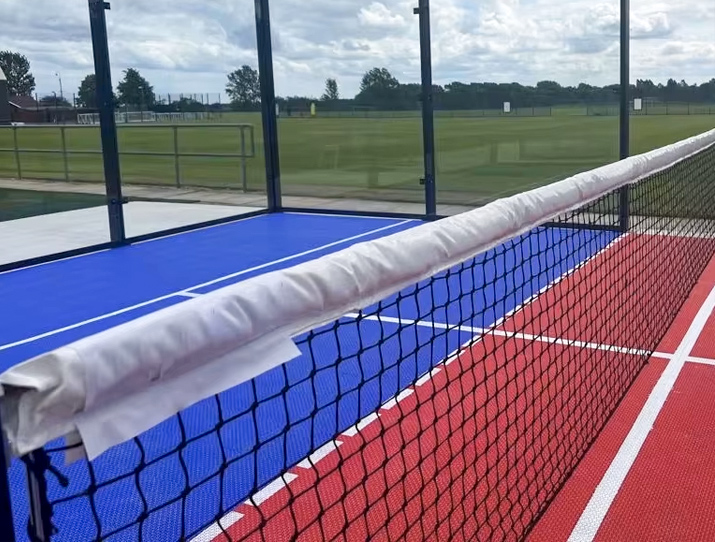

4. Flooring System – Choosing the Right Surface

The flooring plays a major role in player comfort and safety. The most commonly used surfaces are:

- Acrylic sports flooring

- Artificial turf with shock-absorbing pads

- Indoor sports PVC flooring

Ideal flooring characteristics include:

- Non-slip surface

- Water drainage (outdoor courts)

- Elasticity for safe landings and quick foot movement

Shock pads may be added underneath to reduce impact on knees and ankles.

5. Installation & Assembly – On-Site Construction

Once materials arrive on-site, the assembly begins. Installation typically takes 3–5 days, depending on weather and ground conditions.

Steps include:

- Ground preparation

- Leveling the ground

- Pouring the concrete subbase

- Steel structure assembly

- Column and frame installation

- Bolting and structural reinforcement

- Tempered glass mounting

- Panels installed with safety anchors and stabilizers

- Net system installation

- Rebound nets tensioned according to federation standards

- Lighting and electrical setup

- LED sport lights positioned to eliminate shadows

After assembly, detailed testing is performed:

- Impact test on the glass

- Tension test on the nets

- Electrical and lighting checks

Once everything passes inspection, the court becomes playable.

6. Final Delivery – Turnkey Padbol Court

A professional delivery includes:

- Court cleaning and inspection

- Gameplay test with a trial match

- Maintenance and care training for the operator

At this stage, the investor receives a fully playable Padbol court, including optional items:

- Branding & custom color options

- Scoreboard systems

- Seating or lounge area design

- Fencing or roof systems for outdoor courts

A high-quality turnkey supplier manages all steps: design → production → installation → delivery without the customer needing multiple contractors.

How Long Does It Take to Build a Padbol Court?

- Production time: 15–30 days (depending on volume)

- Shipping: varies by country

- Installation: 3–5 days

How Much Space Do You Need?

A court requires 20 x 10 m of playable area, but the working space should be at least: Minimum recommended: 25 x 15 m

This allows space for safe installation and player movement around the structure.

Is Building a Padbol Court a Good Investment?

Padbol is becoming popular globally because:

- Low construction cost compared to tennis or padel

- Fast return on investment

- Attractive for hotels, resorts, sports clubs, municipalities, and investors

Many facilities amortize the investment in 6–12 months through:

- Hourly rentals

- Tournaments & leagues

- Corporate sponsorships

Building a Padbol court is not only a construction project — it is an investment into a rapidly expanding sports market. With proper planning, quality materials, and professional installation, you can offer a unique, exciting, profitable sports experience.